Product Advantages-Core Components and Technological Excellence

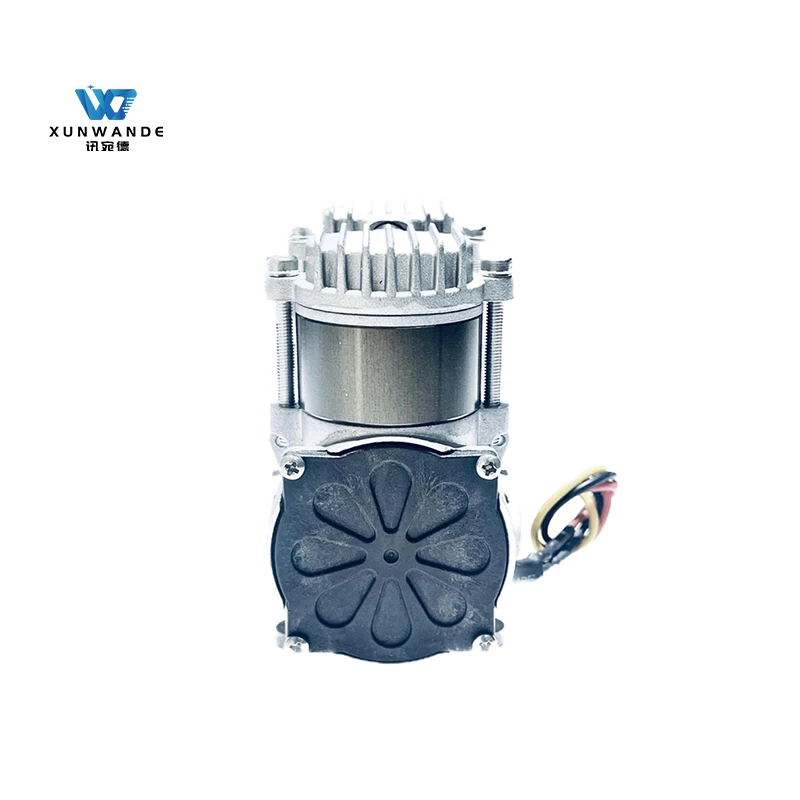

XWD’s pump product portfolio highlights: Energy efficiency (BLDC) and low noise (<47 dB).

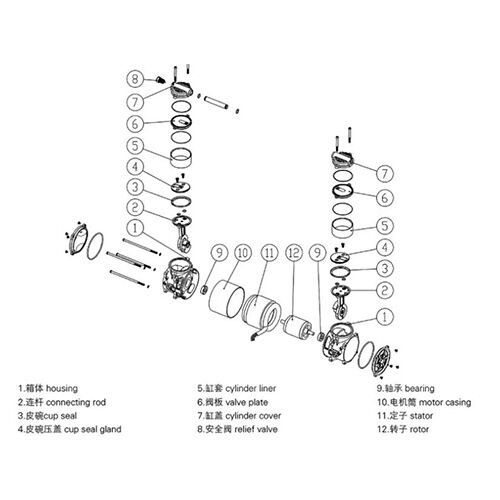

Key Components: Cylinder, piston, bearings, crankshaft and connecting rod, metal valve plates, seals, motor, aluminum housing, explosion-proof capacitor.

Core Advantages of XWD Oilless Air Compressors and Vacuum Pumps

1. Material Excellence

Core Materials:

1. Baosteel Silicon Steel Sheet (DW800): Stable performance, low loss, high efficiency.

2. DuPont Insulation Varnish (USA): Withstands temperatures up to 180°C, ensuring long-term durability.

3 .Elantas Water-Based Insulation Varnish (Germany): Eco-friendly and heat-resistant (155°C).

4.Kingfa Technology Plastic Components: Compliant with flame-retardant standards.

5.Premium Bearings: NSK, TPI, and ERB bearings for enhanced reliability.

Certifications: All components pass ROHS/REACH tests, guaranteeing environmental and operational safety.

2. Advanced Manufacturing Processes

Precision Machining:

· Bearing seat dimensional tolerance ≤0.001 mm, roundness ≤0.0005 mm, with 100% full inspection.

· 36 Korean-imported CNC machines ensure high precision and production capacity.

Surface Treatment: Critical components (e.g., valve plates) feature wear-resistant coatings (e.g., tungsten carbide) to extend service life.

Quality Control:

1.Three full inspections during motor and compressor production.

2.Full performance testing before shipment, followed by random sampling by the quality department.

3.Certified to ETL, CE, ISO 9001, ISO 13485, ensuring compliance with international standards.

3. Performance Superiority

Efficiency & Stability:

· Motor temperature rise controlled below 85°C; coil temperature ≤110°C under 242V voltage and 28°C ambient conditions.

· Clear correlation between system pressure and flow rate, adaptable to diverse equipment requirements.

Energy Saving & Noise Reduction:

· Noise levels as low as 53 dB, ideal for noise-sensitive environments.

Modular Design: Critical components (e.g., diaphragms, valve plates) are quickly replaceable, minimizing downtime and maintenance costs.

Key Innovations in XWD Oilless Air Compressors

· Compressor Head: Precision-engineered for optimal airflow and durability, ensuring oil-free operation.

· Rocking Piston Compressor: Reduces friction and vibration, enhancing efficiency and lifespan.

· Oil-Free Air Compressor Head: Eliminates oil contamination risks, perfect for medical, laboratory, and food-grade applications.

XWD’s oil-free air compressors combine cutting-edge materials, rigorous manufacturing processes, and innovative design to deliver unmatched performance, reliability, and compliance with global standards. Ideal for industries demanding 100% oil-free air, these compressors set the benchmark for clean, sustainable compressed air solutions.